By Mike Lehman

What is the MILL?

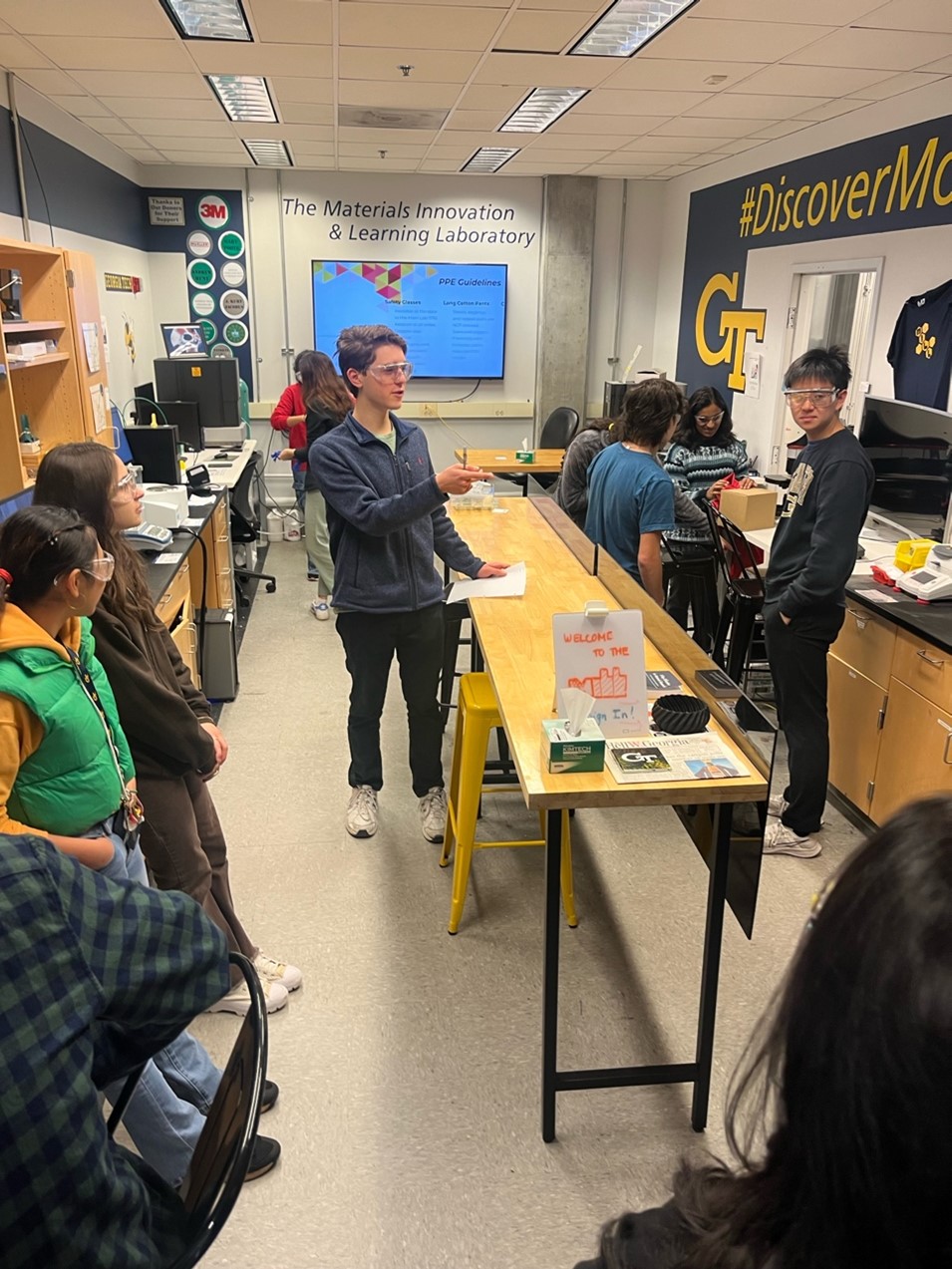

Opened in 2016, Georgia Tech’s Materials Innovation and Learning Laboratory (MILL) was the first undergraduate-run make-and-measure space dedicated to Materials Science and Engineering (MSE). The MILL is designed to mimic the real-world process of creating new materials and offers undergraduate students the opportunity to not only understand characterization, measurement, and processing, but also to be involved in cutting-edge research and maintenance and utilization of sophisticated processing equipment.

The MILL, GT Women in Engineering

During a tour of the MILL, Ella Parker, the MILL’s Chief Communications Officer, explained, “What makes us unique isn’t that we’re a maker space, it’s that we’re a make, measure, and learn space, so it is about understanding. Not only can we create it, but we understand how it works on a micro level, and we make sure it continues to work.”

The core of the MILL is student involvement and understanding of how materials work. While the lab is divided into three primary areas—characterization, measurement, and processing—it is also looking for ways to expand its mission to support biological materials by adding a clean room and experimental printing labs in the near future. Combined with industry connections in Atlanta, the MILL offers opportunities to gain practical skills that several members have leveraged into positions after graduation.

Characterization Area

One of the standout tools in the characterization area is the Leica optical microscope, which offers resolution up to one micrometer, or about 2,000 times magnification to help dissect the physical structure of materials. Students and researchers can use Leica to examine the microstructure of materials. A notable recent project used this technology to analyze 3D-printed stainless steel. Ella explained that student researchers utilized a Z-stack technique, which involves taking several images at different depths, to explore what the core’s internal structure looked like in 3D.

Leica Optical Microscope, GT Women in Engineering

In addition to the Leica optical microscope, the characterization area has a surface topography machine that allows precise measurement of surface roughness and inclination. Here, researchers can analyze different process methods that affect the surface characteristics of materials. The Fourier-Transform Infrared Spectroscopy (FTIR) instrument further affords analysis of polymer and glass samples. Ella explained that during the recent solar eclipse, FTIR helped confirm the material makeup of safety glasses based on their topography. “We did this with the glasses that everybody was using for the eclipse, and so we confirmed they were made out of PET,” she said.

Scan of Eclipse Glasses

One of the most exciting pieces of equipment in the characterization area is the scanning electron microscope (SEM), which is unique to the MILL. This tool has been used in several interdisciplinary research projects, including the study of soil samples by students in the biology department. “We are the only maker space on campus where you can use a scanning electron microscope for free. Everywhere else is roughly $40 an hour,” Ella emphasized. Student workers in the MILL also manage the SEM’s maintenance, which provides hands-on experience that is rare at the undergraduate level.

Measurement Area

The measurement area provides equipment for testing for tensile and compressive strength, microhardness, contact angle measurement, UV-Vis spectroscopy, density, and thermal properties. The primary tools are the Instron and Mark 10, machines used for various mechanical tests, including cyclic testing and tension tests. In a recent project, students used the Instron to perform a three-point bend test on copper samples utilizing different machine fluids. “With this equipment, you can figure out a lot about the fatigue component, or how long [a material] will last, or creep. You can also do cyclical tension tests, where you pull in tension and then put it back, and repeat so that you can learn about your material and what it’s capable of,” Ella noted.

The contact angle gyrometer is another machine that aids in measurement. With the machine, researchers learn about free surface energy and can measure how many unsatisfied bonds are present on the top of a surface, which is especially beneficial in battery research. For measurement, you drop a known liquid, typically DI water because of convenience and safety. The contact angle of the droplet on the substrate lets you read surface energy.

Processing Area

The processing area is equipped with several 3D printers for experimentation with different materials. The printers can use resin, steel-infused filaments, and wood-infused filaments. Recent additions are new dual-color and dual-material printers, which open new possibilities for complex prints. “We can print squishy things,” Ella noted, showcasing equipment capabilities.

While the 3-D printers use specialized filaments, the MILL is taking special care to consider environmental sustainability. To address the waste generated by 3-D printing, the MILL uses a granulator to recycle used filaments which is then processed in the lab’s extruder to create new filaments.

X-Ray Equipment

A primary feature of the MILL is the X-Ray equipment, including XRD and XRF machines, which are used for material verification and analysis. As Ella explained, these tools can create “unique fingerprints of materials,” helping to identify the composition and structure. “These would be like the Sherlock Holmes of material science equipment,” she said. The X-ray machines are also used to train staffers, for which they attempt to discover the composition of “mystery mixes” to learn how to interpret results.

X-RAY Equipment, Staff Training

Getting Involved

As a student run maker, learning, and discovery space, the MILL has opportunities for students to join at the beginning of the fall or spring semesters. Introductory events allow incoming students to learn about the lab and meet the community. Each member goes through initial training that covers the basics of lab safety and equipment operation before entering specialty roles. General staffers typically work three hours per week. Once they gain experience, they can pursue other roles, such as Training Officer (TO), or join Learning and Discovery (L&D) teams. TOs are responsible for maintaining specific machines and troubleshooting to make sure they are available for use. Recent TOs revitalized a donated high-temp 3D printer, working on the machine until it was functional. This type of experience creates opportunities for staffers to learn specific machines better than many people in industry.

L&D teams focus on specific research areas, including textiles, sustainability, the science of sports, and 3D metals, among others. “If you have a project you’re really interested in, or you really like one of the L&D groups, you can work to become an L&D lead,” Ella explained. Each team operates semi-independently and offers opportunities to work closely with specific instruments and machines.

The MILL is open to all majors, and the diverse range of equipment attracts research projects from many departments. “We have a constant influx of students from different majors because of the interdisciplinary nature of our equipment and research,” Ella noted.

The MILL Moving Forward

The MILL is entirely run by undergraduates and mirrors other maker spaces where there is a Chief Training Officer for each section, an executive board, and student staffers who oversee different machines. The structure gives students learning opportunities in managing and maintaining advanced equipment. The MILL offers unique opportunities for undergraduate students to gain hands-on experience with industry-specific instruments and machines. “Everything in here, a student is responsible for,” Ella emphasized, highlighting the experience students gain.

Google and Delta Tours

Looking into the future, the MILL has plans for further expansion and industry collaboration. “We want to build it out,” Ella mentioned. There are plans to expand the MILL, which includes adding a clean room and equipment to support research in biological materials. While the lab has established partnerships with companies like Novelis and Delta, there are continued efforts to create more connections in industry for students through co-op opportunities. These partnerships enhance students’ resumes and provide practical experience and networking opportunities that are highly beneficial in their future careers.

Visit the MILL website or schedule a tour to learn more.